Additive

Minimize risk and ensure high-quality, certifiable additive manufacturing parts with Ansys’ comprehensive and scalable software solution. Create and optimize designs for topology, lattice optimizations and more.

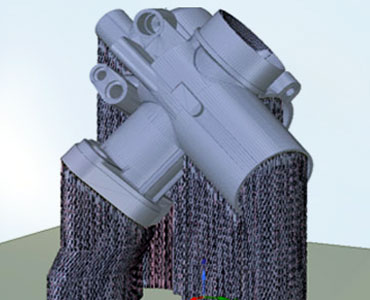

The basic principle of Additive Manufacturing technology is that a CAD generated 3D model is used directly to fabricate a three-dimensional object by adding layer-upon-layer of material and fuse them together.

High level features

Ansys Additive Solutions, a comprehensive and scalable software solution, allows you to minimize risk and ensure high quality, certifiable parts. Dive deeper into the properties of your printer parts, ensure traceability of your data, optimize build files and more. Our software lets you create additive manufacturing designs and simulate the metal additive manufacturing process to reduce product development time. An end-to-end manufacturing solution, Additive Solutions spans across multiple Ansys product offerings.

Additive Suite spans the entire workflow – from design for additive manufacturing (DfAM) through validation, print design, process simulation and exploration of materials. Additive Suite includes:

A prep step for simulation and printing, Additive Prep includes a preparation tool and quickly generates support structures.

Choose parts correctly the first time on Metal AM Equipment with Additive Print, a standalone solution for Additive Manufacturing Process simulations.